Have you ever wondered how jewelry is made? Jackie Cohen of My Story Jewelry walks us through the process.

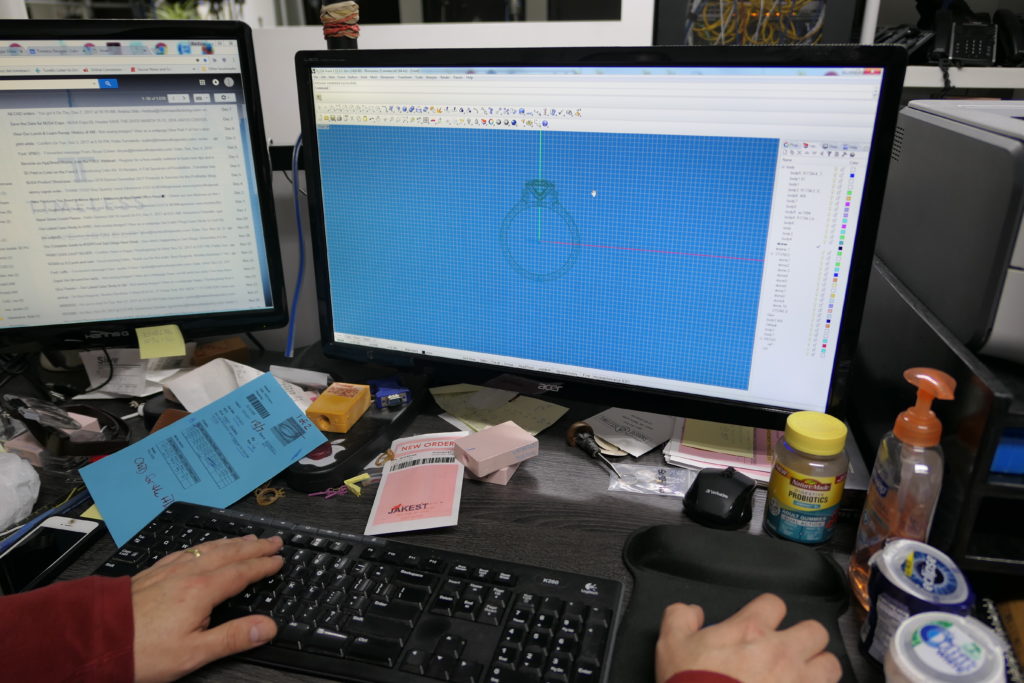

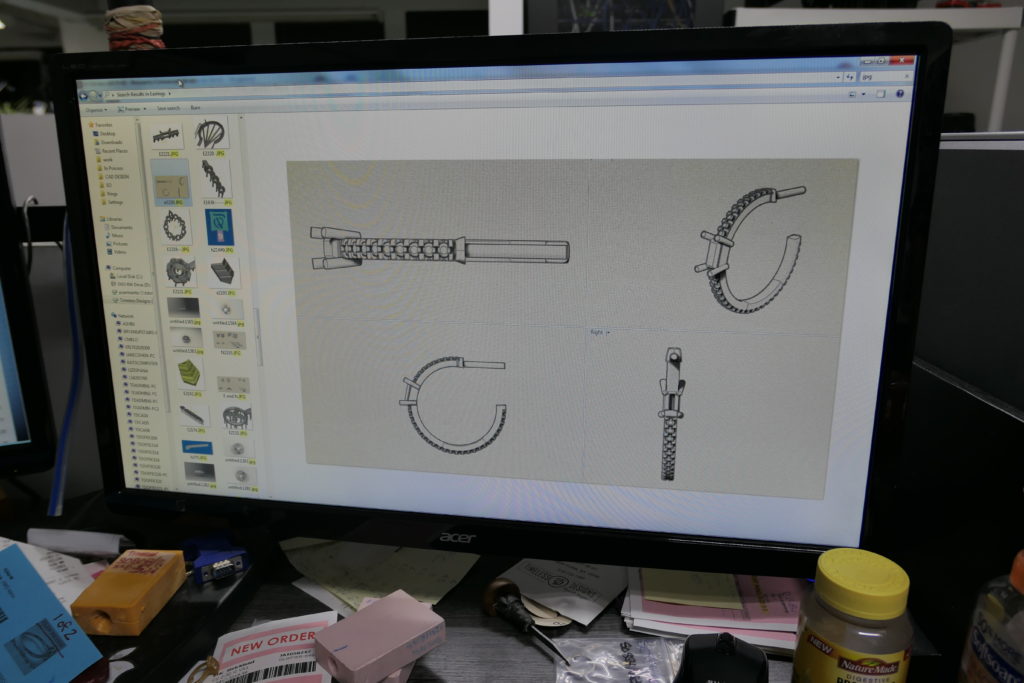

Everything starts with a CAD (computer aided design) which is a software tool that creates a prototype for models which can be rendered into 3D designs. The 3D designs are printed into a wax. The wax then gets sent to a caster to be cast into a piece of metal (Yellow Gold/Rose Gold/White Gold/Platinum).

Click here to watch: Showing an earring in 3D

Tell us about casting

Most people outsource casting since it involves a lot of requirements. The model lives at the caster, and you order the number of units in a specific color of that piece. The caster sends the raw piece of metal to you and it goes into a workbag. The workbag has the breakdown of the stones (example 16 round diamonds with a specific size, setting type, any components – earring back etc). Price is determined by the weight, setting style and the labor.

Once a workbag is made, the raw casting goes into the factory for production. They begin by cleaning it. The next step is to size the ring (if necessary). A jeweler sizes a ring by cutting the shank, and then seams it together with a laser machine to make it a smaller or larger size. It has a light with a torch, so you’ll see actual fire coming out. Then the item goes into pre-polish. After each process the piece of jewelry then goes through quality control where the QC (quality control) expert will look at the piece under a microscope.

Click here to watch: Buffing the ring so all the sides are even

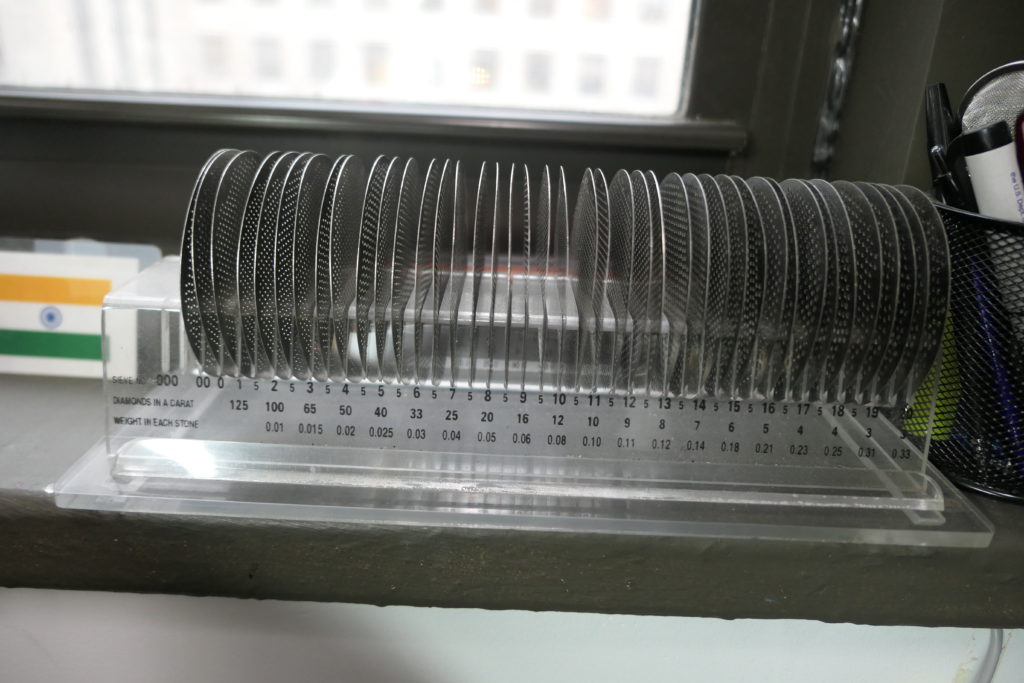

Click here to watch: Sifting through to find the right size diamonds.

What happens now?

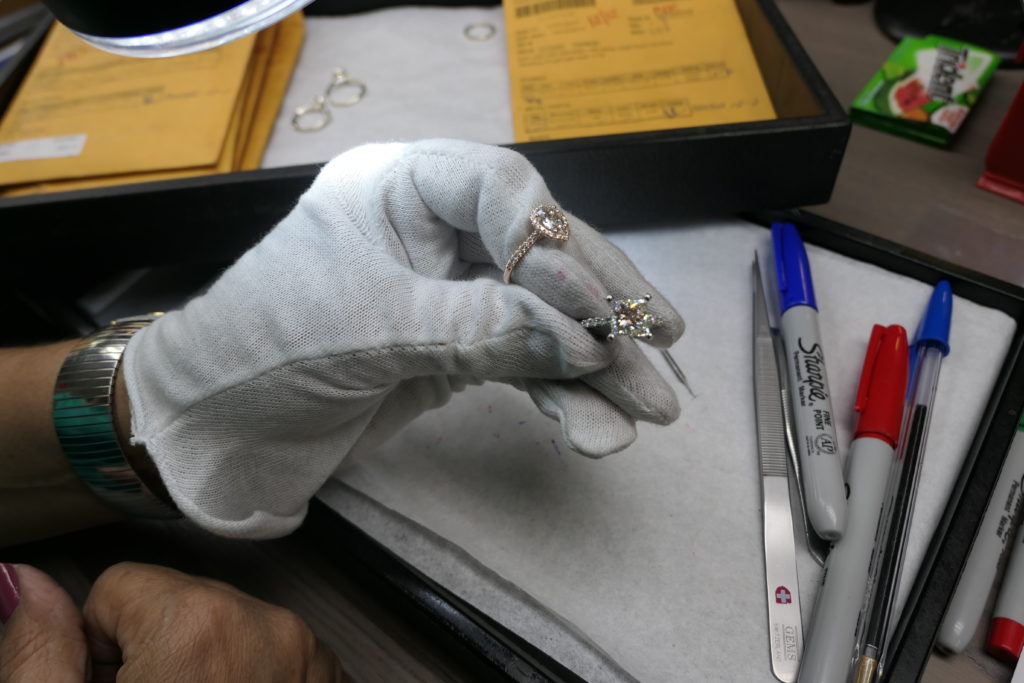

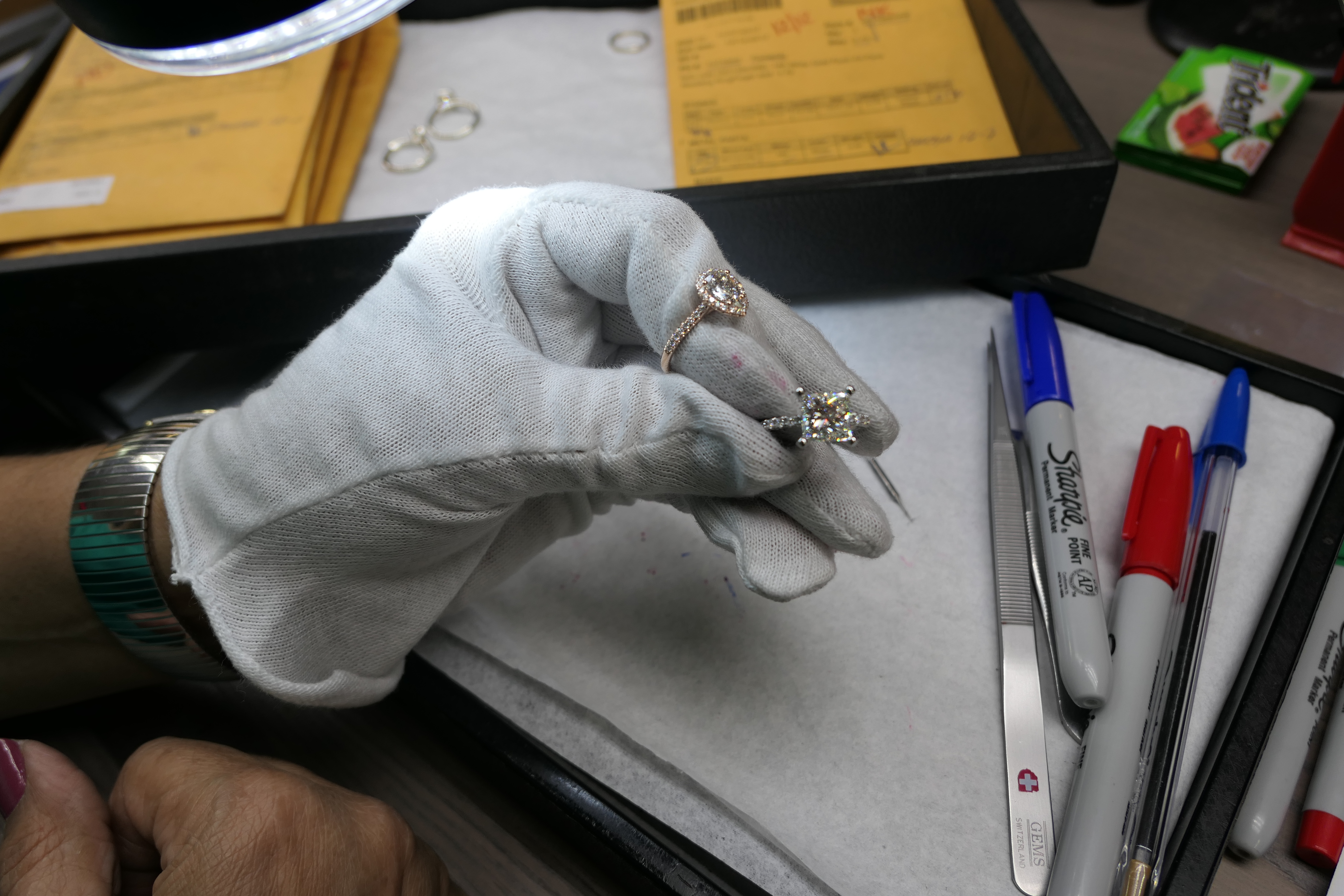

Next, it goes into picking, sifting & sorting where you pick the diamonds and gemstones, etc. in a secure area. They scan the workbag and they take the stones out of inventory. The position of “Setter” is the most elevated of the process. They make the most money and are the most skilled craftsmen. Every time they have a different ring to size or new size stone, they change the piece of machinery that they use. Then it goes back to quality control to make sure the stones are perfectly aligned & secure.

Click here to watch: Polishing the ring

Click here to watch: Adding the rhodium plating

How to make it shiny?

There is a pre-polish and a final polish. The last step is polishing, rhodium plating, yellow, white or rose gold plating etc. This happens in the washout room. Finally, they have the last quality control check. One unique ring goes in one workbag and it travels throughout the whole process.

Click here to watch: Polishing & washing the rings

The Style That Binds Us

BY

you said: